Welcome to the latest entry on the DIENES blog. In previous entries, we have discussed the different aspects of each slitting method used in the industry. We also discussed the considerations and factors that affect the outcome of each type of slitting method. In this blog, we will discuss the considerations needed when choosing between a shear vs. crush cut application and when to choose each one.

Shear vs. Crush: Difference Between the Two

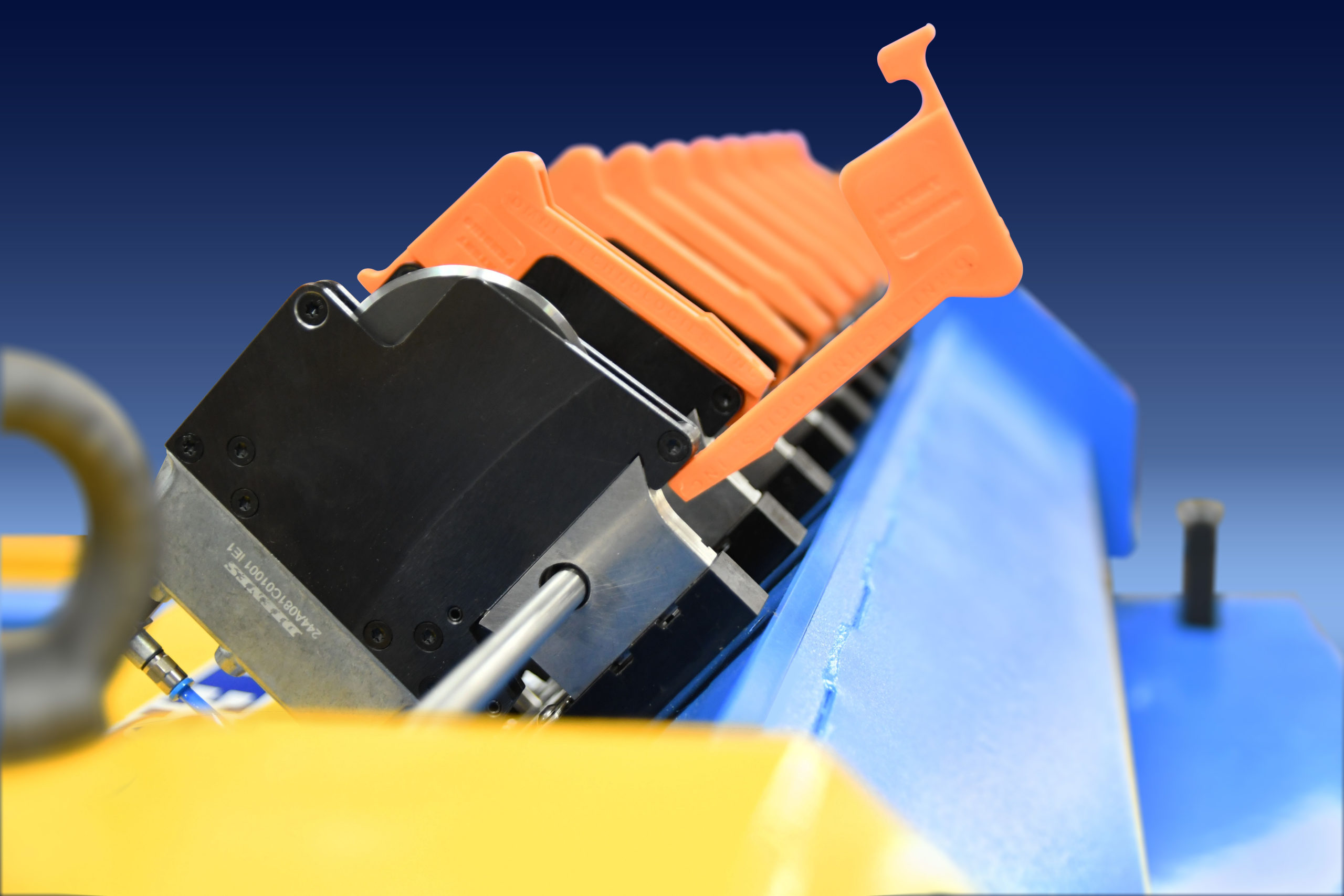

First, let us have a quick reminder of each slitting method and the components needed for each application. As mentioned before, crush or score cutting uses brute force to penetrate a knife blade through materials. Usually, a pneumatically powered knife blade holder applies this force against a hardened anvil roll. The picture above shows a crush slitting application.

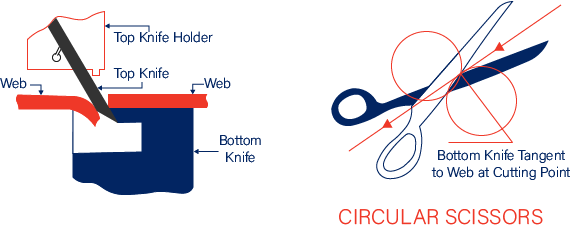

While shear cutting or shear slitting is the type of slitting that uses a combination of a top and bottom knife with defined geometries. Creating a shear force on the material as it separates going through the cut point.

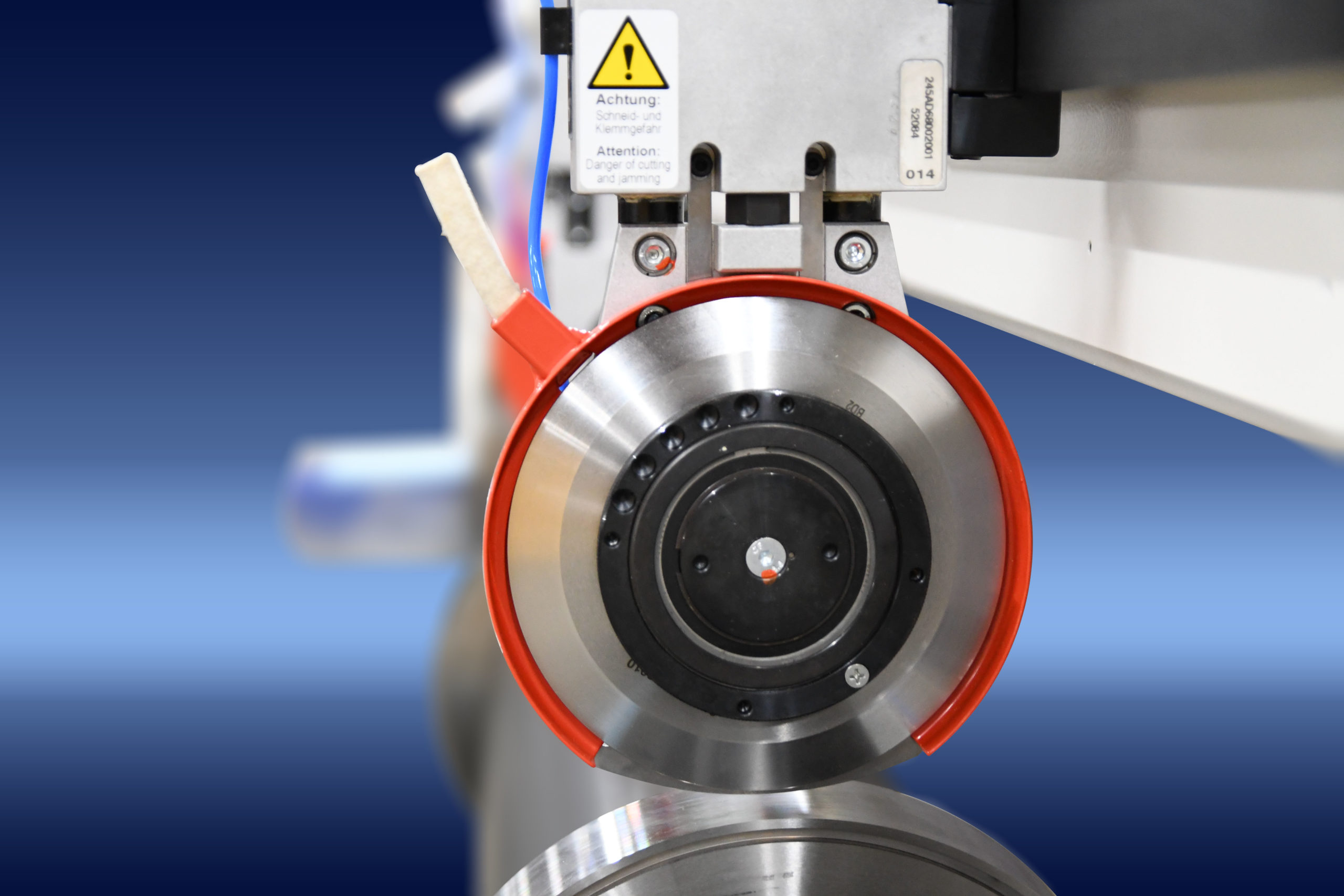

The main idea behind shear cutting is to replicate a pair of circular scissors. These “scissors” cut the material exactly at the cutting point, providing the material with a clean-cut edge. The picture below shows an example of a shear slitting application.

Which Method is Easier?

Crush cutting is the easier slitting method out of the two. It does not require any set-up parameters and considerations. Other than the holders, which are mounted completely squared against the mounting surface.

On the other hand, shear cutting requires the operators to position the top and bottom knife. Operators position them at a certain distance from one another. They also set-up the amount of overlap from the top to the bottom knife.

Shear vs. Crush: Which one Requires less Maintenance?

Crush slitting typically requires less maintenance since the knives are not perfectly sharp. The radius on the score knife tip can last much longer in comparison to a shear style top and bottom knife edge.

Periodically, in shear slitting, both top and bottom knives need to be resharpened. As they are required to have a sharp cutting edge. Yes, the bottom knives as well.

What Edge does Shear have over Crush?

What Edge does Shear have over Crush?

Additionally, when considering costs, crush cutting components are also less expensive than shear cut components. So, one may wonder, why is shear slitting still used? And the answer is quite simple actually: because of the quality of the resulting cutting edge. Shear slitting delivers a much cleaner and uniform cutting edge in all applications that crush cutting applications cannot match.

A cleaner quality cutting edge is why shear slitting is still widely used in a variety of industries. Even, despite a more complex set-up and slitting process than crush slitting.

Clean and uniform cutting edges are very critical for the materials rewound in the rolls. Using it later in other manufacturing processes.

Having uneven cutting edges in applications such as paper or labels will affect the quality of the product. Therefore, certain industries favor shear slitting over other methods. These industries include:

- Paper production and converting.

- Label production and converting.

- Foils production and converting.

In addition, the amount of dust produced is another reason why industries go with shear over crush slitting. Generally, crush slitting will generate more dust while separating the material. Shear slitting, on the other hand, will produce less dust.

This is very critical in industries such as fiberglass. Large amounts of dust will translate into having an air-born particle of fiberglass floating through the air. This could be harmful to the operators.

On the other hand, some industries favor crush slitting methods. These industries have more wear of components due to the nature of the manufacturing process.

Shear vs. Crush: Which one to use?

By now, you are probably wondering…

Then which of the 2 slitting methods should I use? Shear vs. crush?

The answer is again quite simple. It depends on the cutting-edge quality that your process requires.

- If a very clean and uniform cutting edge is required: then shear slitting would be the preferred method to use.

- If your process does not require the cutting edge to be as clean and uniform: then crush cutting might be a suitable option for your process.

It is important to note that DIENES has developed technology that allows for a much cleaner cutting edge for crush cutting. Users with crush cutting applications can achieve a much cleaner cutting edge than ever in the past. However, despite the improvements, shear-slit cutting-edge quality, cannot be matched 100%.

Also, note that the quality of the cutting edge also depends on the composition of the material itself and the way the materials are held together.

Because of this, whenever we get a quote request for new slitting equipment, we always ask for a sample of the material. Then we can perform some tests using different slitting methods and combinations of blades. This test will determine which slitting method is the best possible outcome.

Shear vs. Crush Slitting Conclusion

So, if you have an upcoming decision to make regarding shear vs. crush slitting and which method to use, do not hesitate to contact one of our experts! We will gladly guide you through the process and help you make the best choice for your application.

Follow us on LinkedIn or Facebook for similar articles like this one!

What Edge does Shear have over Crush?

What Edge does Shear have over Crush?