Pneumatic Score Cut Knife Holder

Back in 1954, Dienes invented the pneumatic score cut knife holder. Today, it still remains the best. But why? Two major reasons: quality and accuracy.

What to Expect with Dienes Pneumatic Score Cut Knife Holder

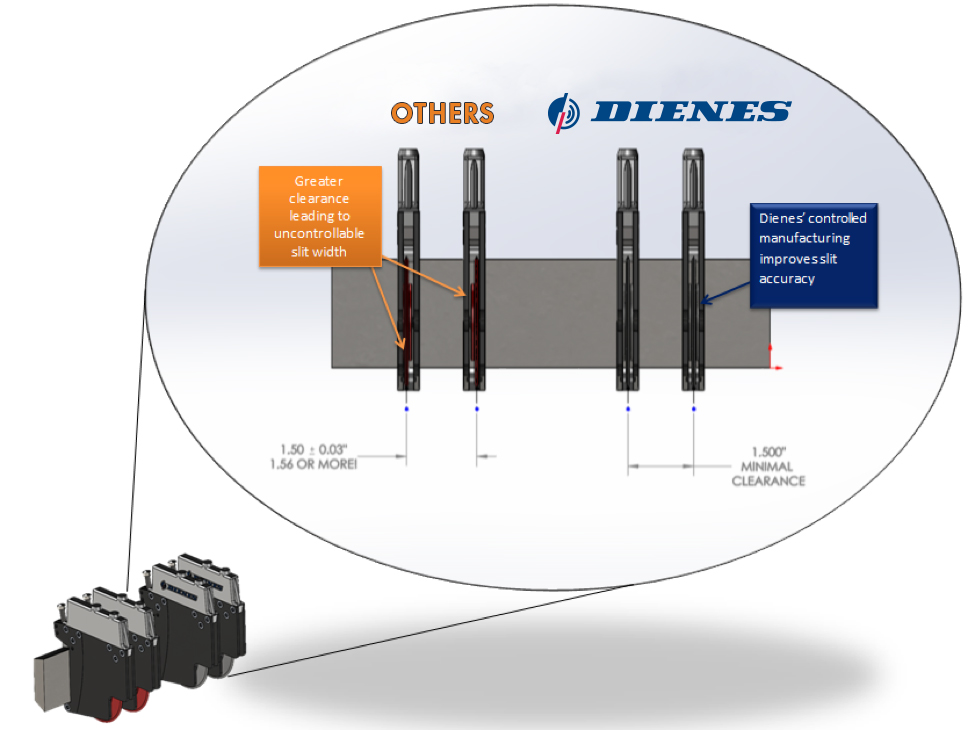

When you purchase a new Dienes score cut holder, you can expect the highest precision in slit width, because of our controlled manufacturing process and high-quality standards in our holder production. It allows us to manufacture a minimal clearance between the blade and the holder. By doing so, we limit the “slop” or movement that the blade can have inside the holder, improving the slitting accuracy and quality by maintaining the blade completely perpendicular to the anvil roll while slitting.

Time to Replace the Knife Holder?

Over time, the holders will wear, and the blade wiggle will increase, impacting the slit width accuracy. So, when is it actually time to replace the holder? Well, according to our quality standard, a holder is still usable when the blade wiggle is below +/- 0.003″, which means the overall horizontal movement does not exceed 0.006″. This amount of blade wiggle is actually not that much, considering the holder is worn out.

You may ask what is the problem with blade wiggling then? After all this talk about blade “wiggle”, holders, and

Assume you have a ½” score cut holder that has a blade wiggle of +/- 0.003″. This in turn would mean that overall you can have a horizontal blade movement of 0.006″. As you can see depicted in the render below, even the slightest blade wiggle translates to a decreased accuracy in slit width by having the blade vary from its cutting position by whatever factor the blade wiggles. This would translate further in an uneven cutting edge and slit width, translating to a higher scrap rate and inconsistent ribbon sizes, ultimately, a decrease in productivity.

Furthermore, a large blade wiggle can also impact the life of the blade and the holder itself. As with an increased wiggle, the blade is more likely to run at an angle on the anvil roll, which would make it run against the side of the holder plate.

Since the blade is in constant contact with a metallic surface (the inside of the holder), its wear is accelerated rapidly and can create a groove, or wear, on the inside of the holder, making it useless in a short period of time.

So not only does blade wiggle impact your productivity and scrap rate, but it also shortens the life of your slitting tools and components.

We Test Our Holders

Our commitment is to deliver the highest quality products to our customers, and we ensure this because we test our holders.

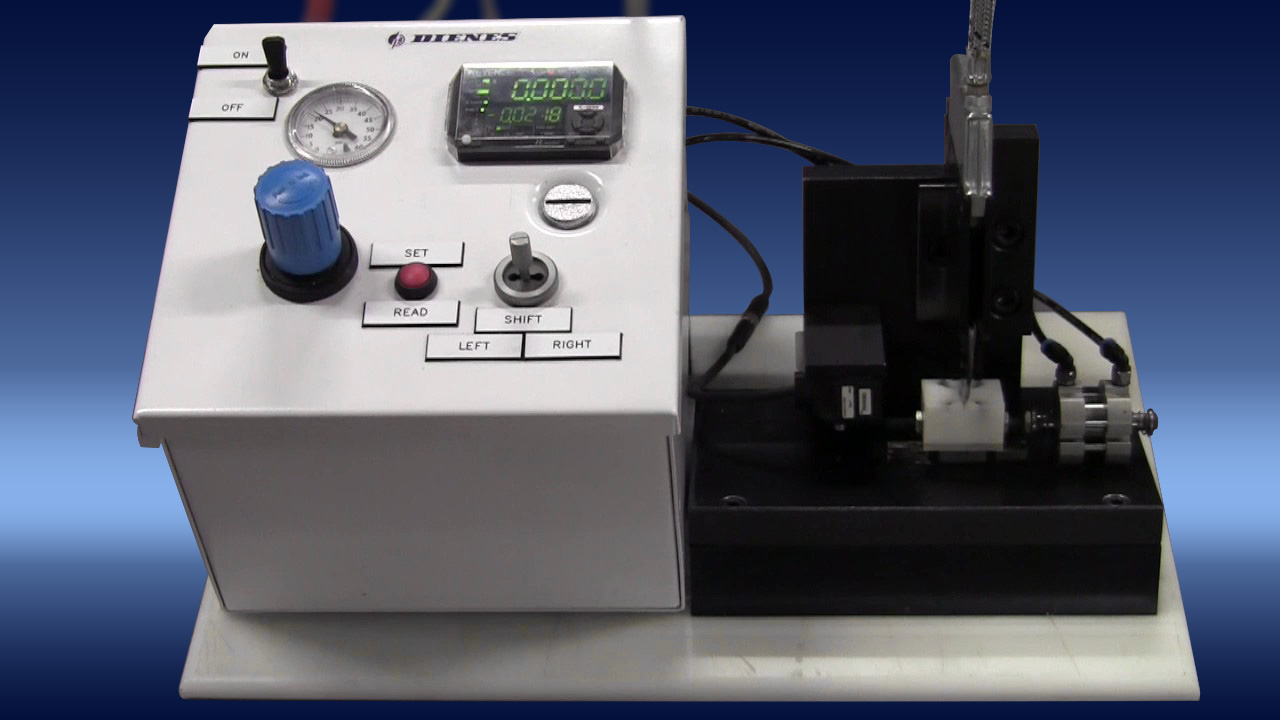

In our pursuit of becoming the industry leader for slitting and slitting related products, we have created a fixture in which we test the horizontal movement or “wiggle” of individual holders.

By mounting the holder to a piece of dovetail bar, once in position, we engage the knife onto the test block. We then move the block sideways through the flick of a lever, first one side and then the other. The system automatically calculates total distance traveled by the knife.

Below is a picture of one of our testing fixtures.

Contact Dienes for Your Pneumatic Score Cut Knife Holder

So now that we have detailed how blade wiggle impacts your productivity and tool life, contact us and we can discuss how Dienes can supply your pneumatic score cut knife holders. Put our 105+ years of experience to work for you!