Is My Blade Sharp Enough?

One of the most common questions we get asked on a daily basis is: How do I know if my blade is sharp enough? Often enough we answer the question with: It depends on how you are slitting.

That response often leads to the look of confusion on our customers’ faces. This might be because there is a common misconception that all blades in slitting should be as sharp as possible in order to cut the material easily and in order to achieve a cleaner cut.

This is the case for most knives and blades in the industry and even in our own kitchens. But, in the case of crush or score cutting, this principle is completely wrong. Let us explain why.

What is Crush or Score Cutting?

Let’s define what crush and score cutting is and the mechanics involved, so we can have a better understanding of why this principle is or is not applicable for this slitting method.

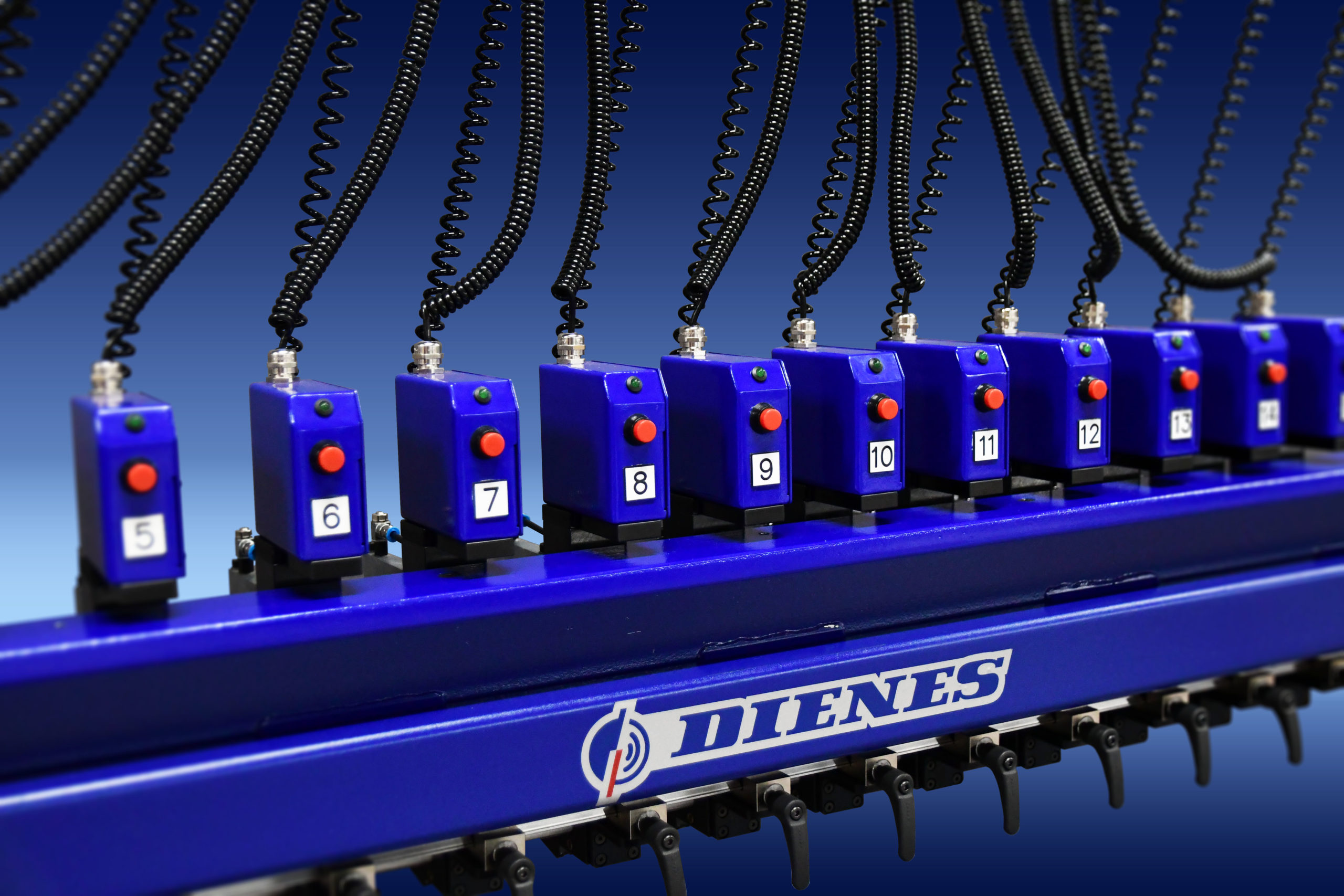

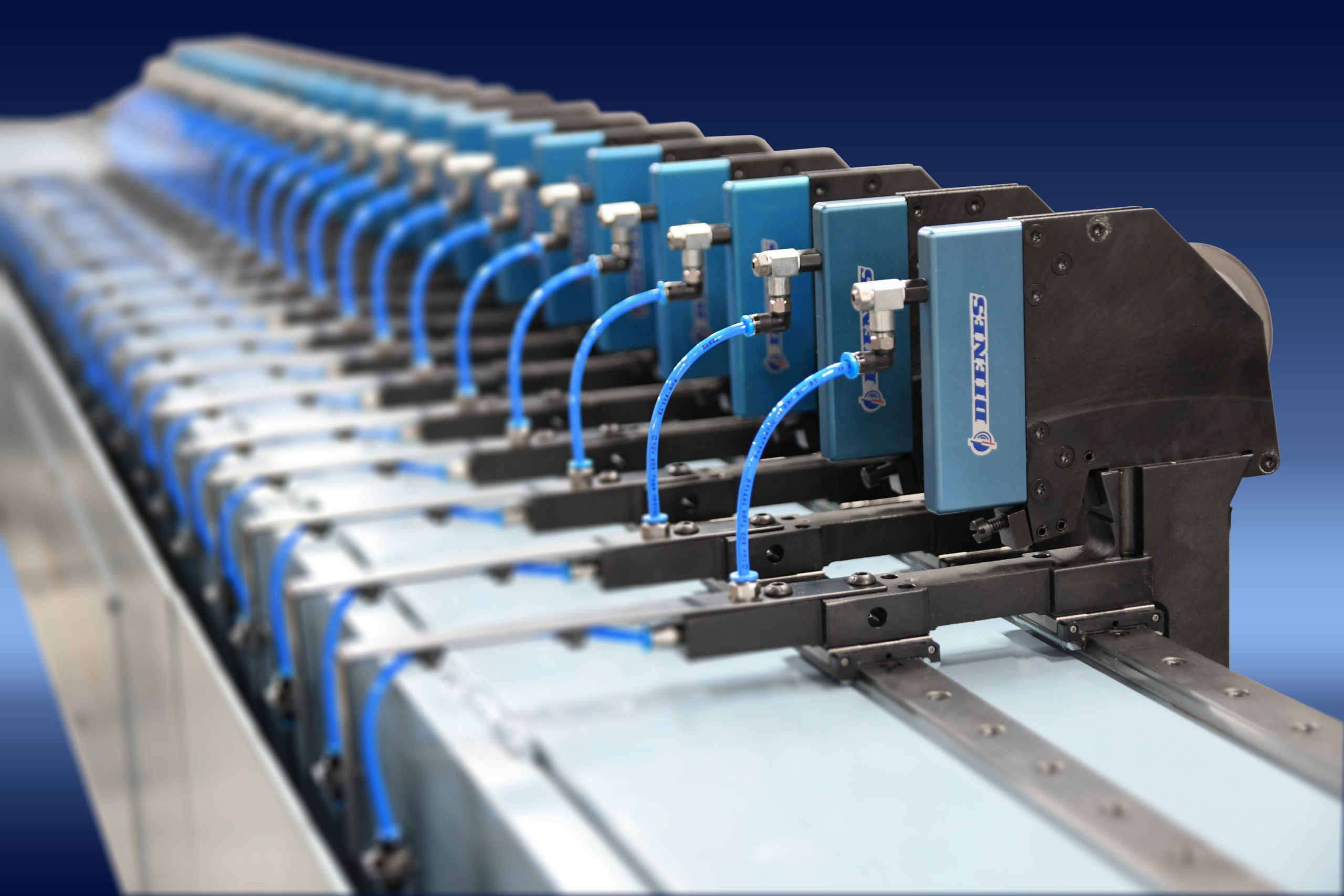

Crush and score cutting uses brute force to penetrate a knife blade through materials. Usually this force is applied via a pneumatic powered knife blade holder against a hardened anvil roll. Crush cutting is generally better for slitting very tough materials such as rubber or sand paper, although some lightweight tissue grades, laminates and adhesive materials fair well with this technique.

With some laminate webs, crush cutting can provide a temporary seal of the multiple layered materials. Crush cutting, also lends itself to heated knife cutting which is useful when cutting adhesive backed webs.

What is the Difference Between Crush or Score Cutting?

Crush cutting equipment costs less than shear components, is easier to set up for different widths, but delivers a rougher edge cut quality. That is why each application requires subjective analysis by both the converter and end user in order to determine whether this slitting method is the correct one for the application.

When a Knife is Pneumatically Loaded Against an Anvil

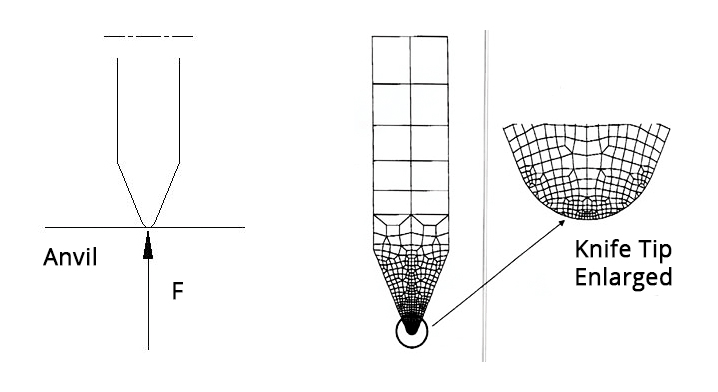

When a knife is pneumatically loaded against an anvil, the force of the contact is applied back up to the blade tip. The material strength of the blade is then opposed by the force being applied down through the knife holder over the area that the knife edge creates against the anvil roll. If a knife edge cannot carry the applied load, it will quickly deform to create enough area for load support, therefore chipping or creating “bald spots” on the tip of the blade.

These images depict the different forces applied when the blade is engaged against the anvil:

DS = F/A, whereby F is the applied cutting load and A represents the Cross Sectional Area of the Knife and DS = Design Stress of the Knife material. Therefore, blade radius and cutting angle selection can significantly influence the effectiveness and quality of the cut, as more radius = more load capability.

Now that we have explained the mechanics and forces involved in this slitting method, let us go back to the effect that different blade radius and the profile of the blades have on the effectiveness and quality of the cut.

Choosing a Crush Cut Blade for Your Application

Below are some points to consider when choosing a crush cut blade for your application, AND some of the blade radius and support angle trade-offs you would experience with different profiles and radius combinations:

- Increasing blade angle will provide more radius support with poorer edge quality

- Increasing the radius will increase knife life but lessen cut quality

- The smaller the radius the less dust generated with a cleaner cut but less knife life

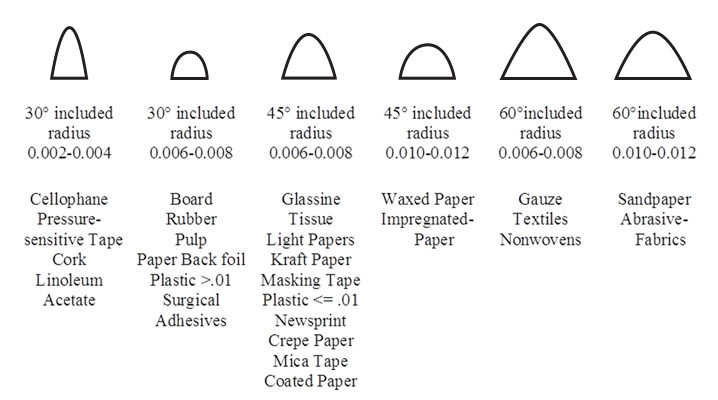

Here is a picture showing different radii, angles and profiles recommended for each application:

The most common crush blade sold today has a 0.004” -.006” (0.10mm – 0.15mm) radius with a 45-degree angle. For new applications this would be a good starting point. Empirical analysis can confirm which specific blade is best for each application – as if a knife life is too short then a larger radius or support angle may be considered. But ultimately, the important point is when crush cutting, a radius should be present at the tip of the blade.

Contact Dienes for Your Blades

As mentioned in the beginning of this article, unlike most cutting methods in the industry, a sharper blade does not necessarily mean a better cut.

Dienes carries a wide variety of blade angles and radii to suit crush cutting of many different materials. We’d be happy to discuss which blade is best suited for your application needs.