In previous blog posts, we discussed the two most common types of slitting; crush, and shear cut. However, there are two additional slitting methods that may not be as common, Razor which offers the cleanest cutting edge, and Heat cut.

Certain applications in the industry may need to use Razor and, Heat cut. In this article, we will provide further detail about razor slitting. We will also present the pros and cons of using these slitting methods over others.

Why Razor Slitting Offers the Cleanest Cutting Edge

The definition of razor cutting (or razor slitting) is the type of slitting that requires a very sharp and small razor that cuts the material. This is why razor cutting provides the cleanest cutting edge possible.

Razor slitting delivers cleaner edges than shear slitting. But the main drawbacks are that the blade life is considerably shorter than shear or crush blades. They also may not be practical for heavier materials because of the sizes available. Therefore, it is used mainly in plastic film, light-gage aluminum foil, and other types of light-gauge foils. Shown below are some of the most common profiles for razor blades.

Here we present a list of some of the most common razor materials and applications in which each are used:

Material |

Application |

| Solid Tungsten Carbide | Paper, Polyester, Cellophane, Nonwovens |

| Solid Ceramic | Films, Copper Foil, magnetic Tapes, Nylon LLDPE |

| Ceramic Coated and TiNI coated | Aluminum Foil, Label Stock, PVC, OPP, Stretch Film |

Performance for razor slitting can either be with a supported web or an unsupported web (also known as in-air cutting). The material being slit and its properties determines the type of web used.

Supported Web for the Cleanest Razor Edge

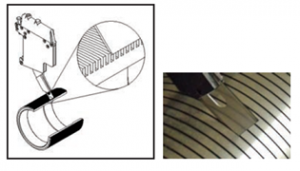

For a supported web, you might use a grooved roll. A grooved roll allows the razor to go in between the roll groves. The material will separate while the web is supported on the roll itself. To the right is an image showing this type of arrangement:

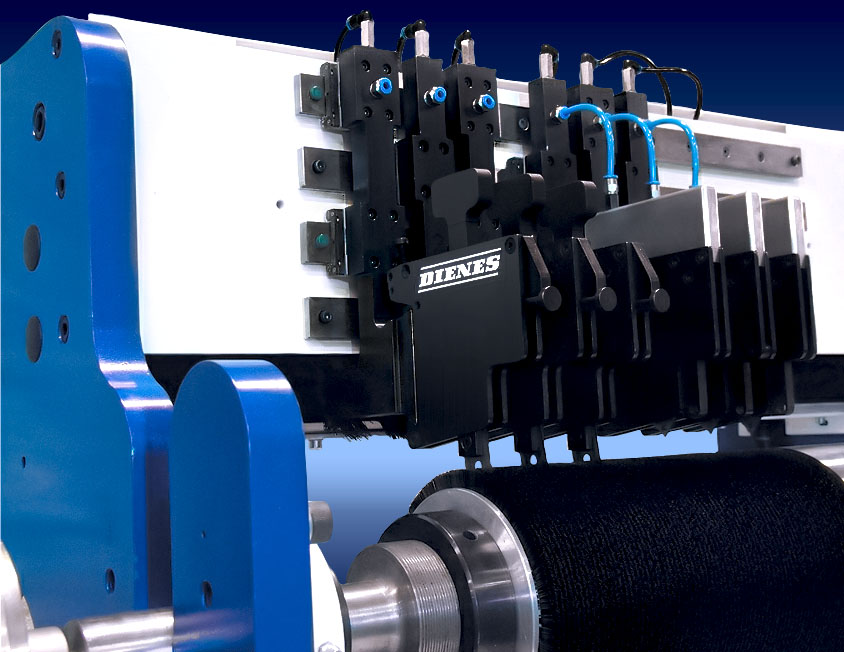

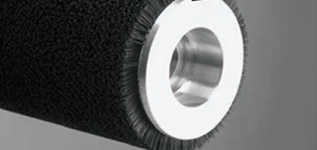

Another method of supporting web is using a nylon brush on the support roll. This type of set-up allows the razor to cut the material on any section of the roll, as opposed to a dedicated cutting lane in the grooved roll. However, this type of set-up cannot reach very high line speeds. Below is a picture of this type of set-up:

Unsupported Web for the Cleanest Razor Edge

An unsupported web set-up requires an entry and exit idler roll to minimize material fluctuation as it passes through the slitting section. It also stabilizes the web, creating a defined tension allowing for it to be slit properly.

Unsupported webs have an advantage over the supported set-ups. This is because it allows the razor blade to oscillate up and down the web. Allowing for the complete edge of the razor to be used extends the blade life considerably.

It also allows for a multi-head razor head set-up. This enables the blade to change over from one to another without losing contact with the web. Also, extending the time between razor blade changes. Below is a picture showing this kind of set-up:

Mechanical or Pneumatic Holders for Razor Slitting

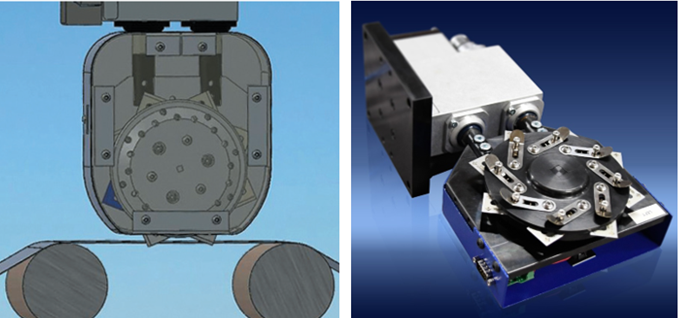

Similar to shear slitting, a mechanical or pneumatic holder can be used during the razor slitting process. Pneumatic holders offer flexibility and some performance advantages. The blade is held in place by a pneumatic piston instead of being clamped and secured by some components.

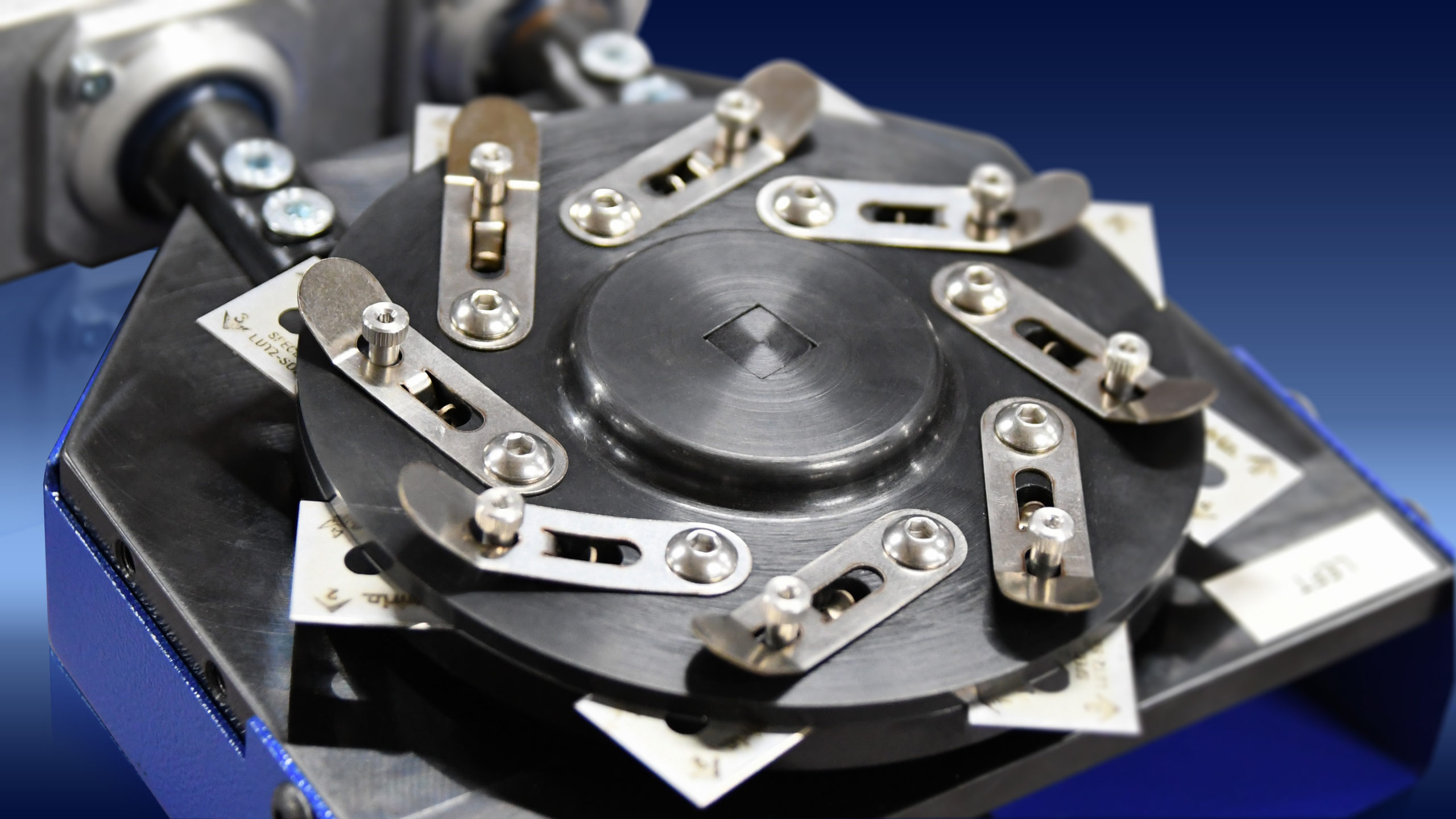

When possible, we recommended using a pneumatic holder instead of a mechanical holder. Below are pictures of showing pneumatic holders in different sizes and arrangements:

Burst Cutting

As we had mentioned previously, razor cutting offers the cleanest cutting edge in comparison to shear and crush cut. However, circular knives do not need replacing nearly as much as razors do.

Therefore “burst cutting” is another solution available in the market. This type of cutting utilizes a very sharp rotary shear knife that operates in a grooved roll. Allowing for a longer blade life along with delivering a clean edge as a razor would. However, if you want the material to be slit with a clean cutting edge, the burst blades need to be re-sharpened constantly.

Conclusion for Razor Slitting

In conclusion, razor cutting offers the cleanest cutting edge. But it comes with a price, being the life of the razor blade. Therefore, users must decide whether a clean cutting edge outweighs a prolonged blade life. This top priority determines the slitting that will be used.

If you are still unsure about what is the best slitting method for your application, we invite you to send us a sample of the material. We will test this material in our slitting laboratory by performing different slitting tests. After testing using the different types of slitting methods available, we will determine and report the results. Do not hesitate to call us today! Follow us on LinkedIn or Facebook for more updates on blog posts!