In previous blog entries, we have discussed in-length the different aspects of the re-sharpening process. Specifically, we talked about how it can and will affect the outcome of the slitting unit. We also mentioned how to make sure your knives are in an optimal state to deliver a quality cutting edge. In addition to re-sharpening, safety precautions and knife handling is also something to consider.

In previous blog entries, we have discussed in-length the different aspects of the re-sharpening process. Specifically, we talked about how it can and will affect the outcome of the slitting unit. We also mentioned how to make sure your knives are in an optimal state to deliver a quality cutting edge. In addition to re-sharpening, safety precautions and knife handling is also something to consider.

However, we have not discussed the proper care and storage of slitting knives. This must take place to preserve their geometry and properties as long as possible. In addition, it will also help avoid having cutting issues or unnecessary injuries from the handling of the knives.

In this article, we will go over some of the best-recommended practices to handle, store, and maintain knives. These procedures will help to ensure your knives will have the longest life possible.

Overview of the 4 Rules: Hardening Process

All slitting knives go through a hardening process to meet certain specifications. This allows the knife to have a lasting blade life and perform a good separation of the material without fail.

However, this process comes with a drawback as it makes the knives less resistant to impact loads or shock loads.

This is true for most hardening processes. As you harden more material, the more brittle it becomes when put under impact conditions.

Safety Precaution #1: Using Safety Gloves for Knife Handling

Therefore, when handling slitting knives, there must be proper care and caution

- Dropping them on the floor

- Hitting them with other surfaces. This damage to the knife may require a re-sharpening process or replacing it altogether.

As a result, the first recommendation for the best practices of knife handling is using safety gloves. Always using safety gloves when handling knives helps avoid knife slipping from the hands of the operators. By doing so, you help avoid accidentally damaging the knife or even the operator.

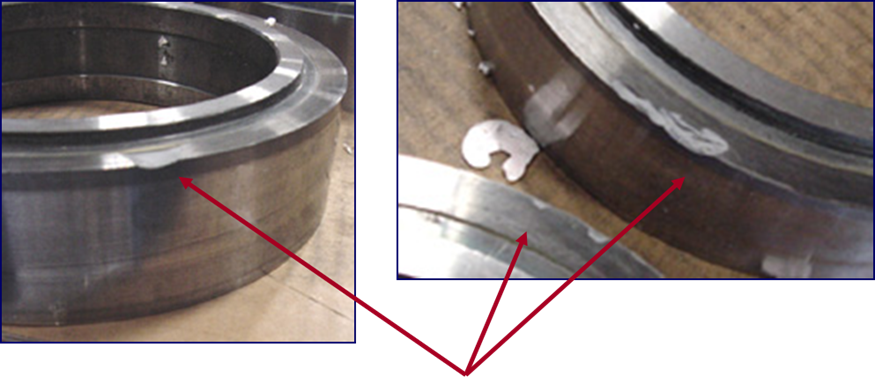

Safety Precaution #2: Damaged Shipping Box

Safety Precaution #2: Damaged Shipping Box

Note that the knives are not very resistant to impact. So, the second-best practice we recommend is to avoid damaging the shipping box that contains the knives.

The damage can impact and cause suffering to all of the knives. This is because the knives typically ship in a cardboard box. Poor handling of the box can easily result in damaging the knives. Below are a couple of examples of how the knives can get damaged from not handling the box carefully.

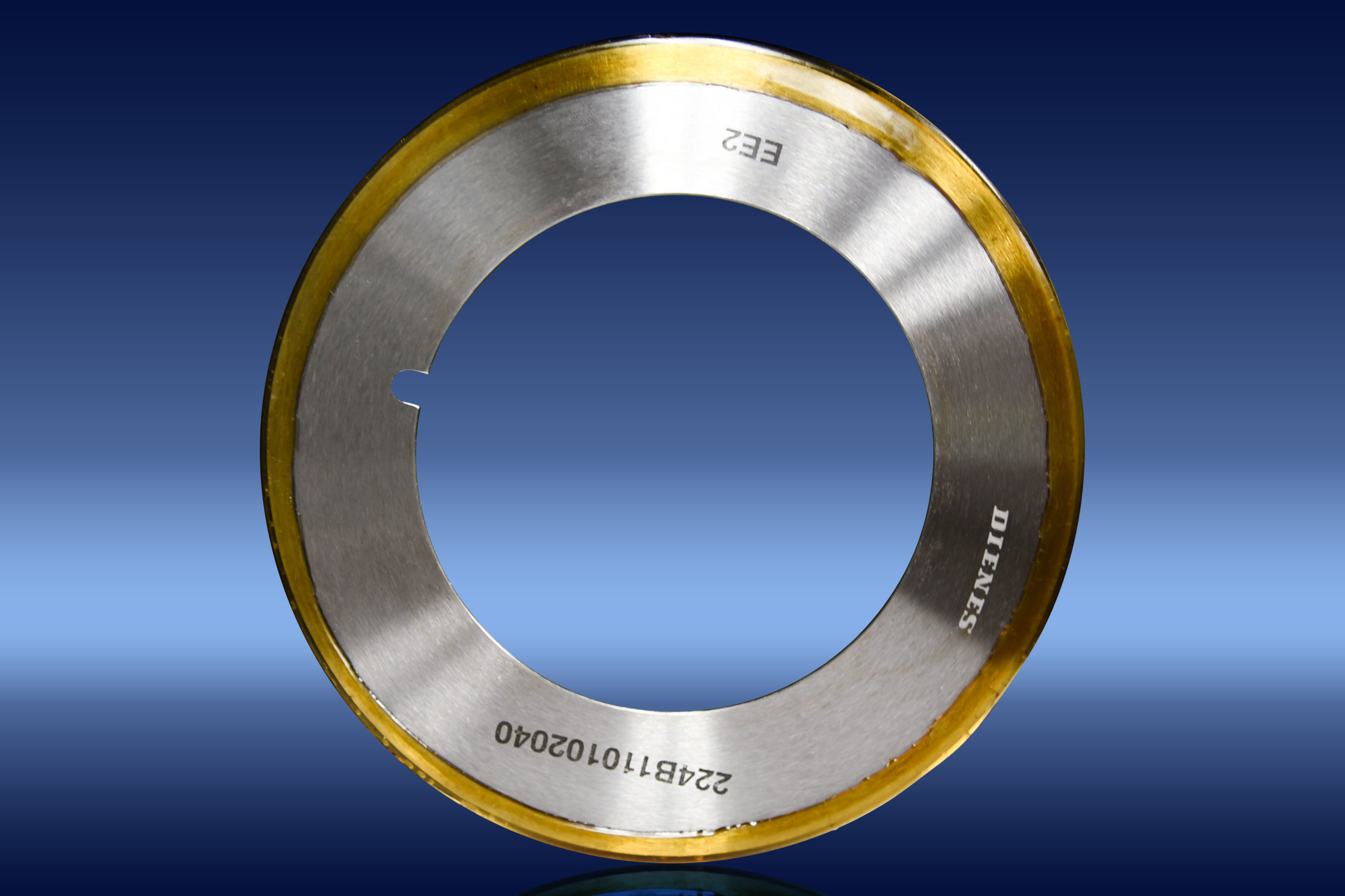

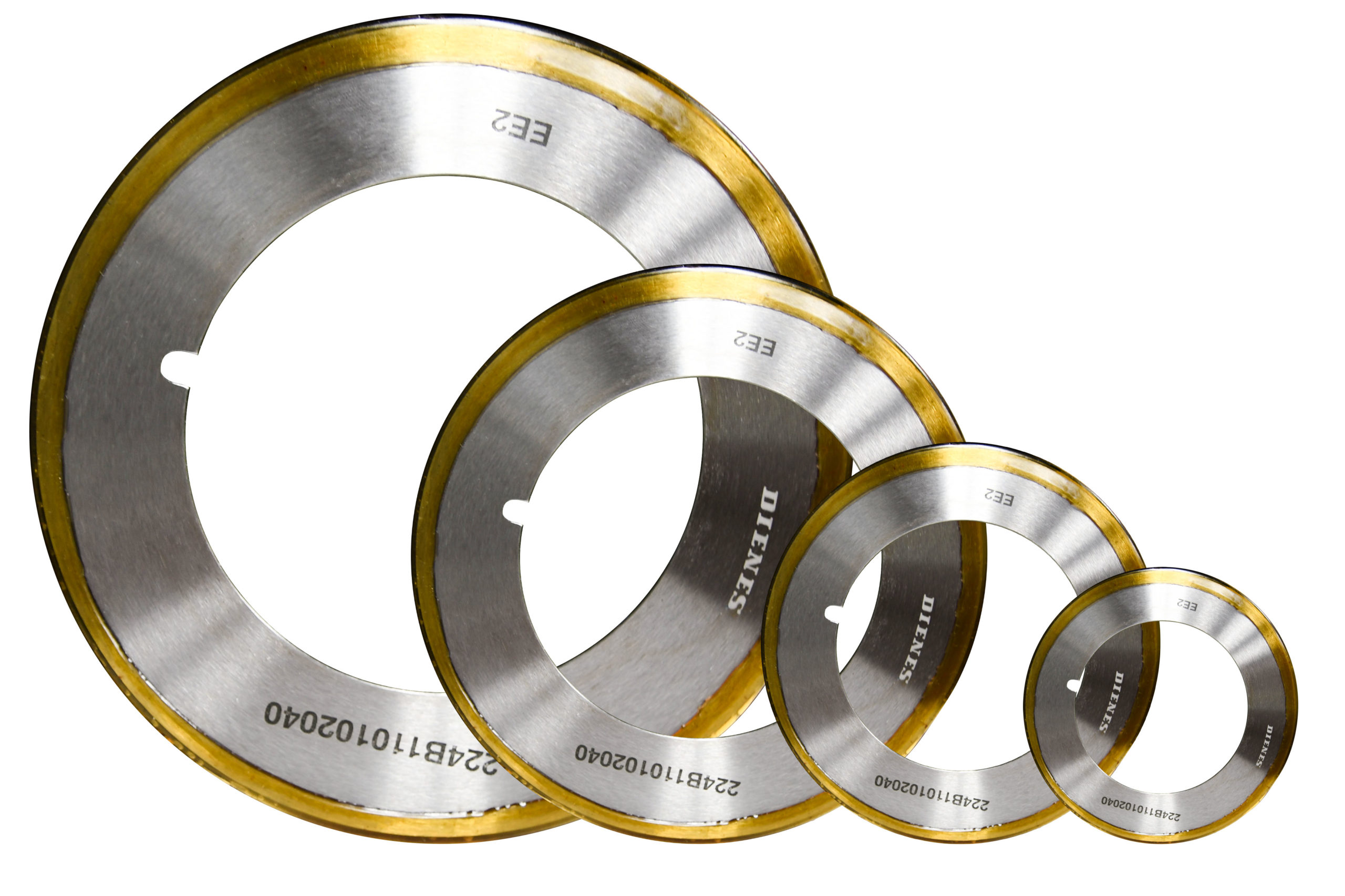

Safety Precaution #3: Protective Coating for Knife Handling

The third best practice for safety precautions and knife handling is (when possible), to use a protective coating. A protective coating will seal the edge of the knife. This is particularly important when storing knives in a warehouse where they might come in contact with other materials. The protective coating ensures that the knife profile will remain intact. In addition, it will also provide the operators with more safety when handling them in and out of the warehouse.

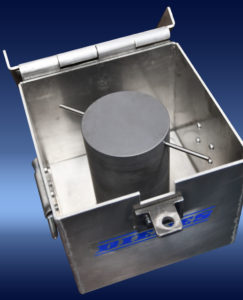

Safety Precaution #4: Special Boxes for Knife Handling

Our fourth and last practice when handling knives is to (when possible) use special boxes. Specifically, when sending or receiving the knives from the re-sharpening process.

These boxes should hold the knives from the inside diameter. However, they should still, have enough space for them to be clear of contact from the outer edges. Below we show one of our boxes that is available for sale in all sizes of knives.

It is important to mention that these boxes have another added benefit. If you are regrinding them as sets, you already know that the knives in the box have the same outside diameter. This is critical for shafted set-ups.

Conclusion of the 4 Rules

Now you know some of the best practices that we recommend for safety precautions and knife handling, storing, and maintaining your knives. If you think that having knife boxes would be a good idea for your facility, give us a call and get your quote today! Follow us on LinkedIn and Facebook for more updates and blogs like this one!

Safety Precaution #2: Damaged Shipping Box

Safety Precaution #2: Damaged Shipping Box