For anyone familiar with slitting applications, we know that there are some big challenges in the day-to-day operations. One of them is the recipe changes on certain production runs. Therefore, this begs the question, what is a positioning system?

Positioning System Recipe Changes

A Recipe Change is:

Widths between each slitting station will have to change depending on the new requirements of the production run. Meaning operators will have to manually move the slitting stations to the newly required positions on the machine.

How quickly or how accurately this process is, largely depends on the type of positioning system the slitting section has. In addition, it is also dependent on the skills of the operators.

In some applications, you may only have 1 or 2 recipe changes per shift. However, sometimes, you might perform as many as 8-10 recipe changes in a single shift!

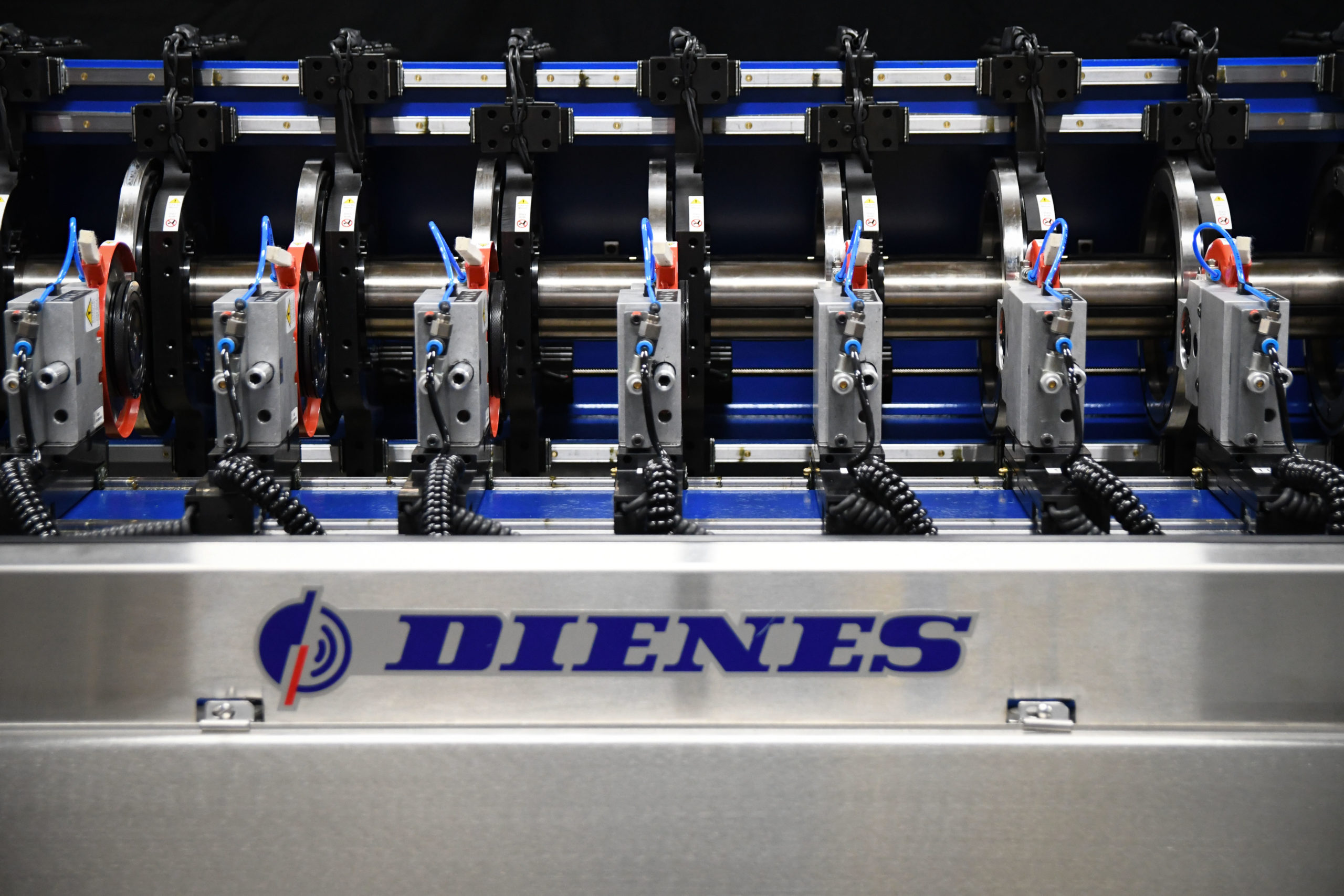

Dienes helps ease our customers the burden of this process, increasing the accuracy and reducing the time spent on performing a recipe change. We offer a variety of positioning systems to fit all of your production processes.

The four different types include manual, semi-automatic, fully automatic, and quick set. A detailed explanation of each is as follows below:

1. Manual Positioning System

Manual positioning systems are systems in which an operator positions the knives by hand. Additionally, utilizing hand brakes, hand wheels, pushrods, and cranks is an option during this process.

These types of systems mount the slitting stations on a dovetail bar or linear bearings. Determining slit widths is done via tape measure or digital readouts with our MD Easy Set option. This provides a real-time feed on the position of the slitting stations.

In conclusion, these types of systems are perfect for applications that do not require so many recipe changes.

2. Semi-Automatic Positioning Systems

Semi-automatic positioning systems: systems in which positioning the knives is under power however, the operator is in control.

The movement of the slitting stations is done via operator buttons and electronically controlled, handheld, or mounted. On the other hand, the operator determines the width of each cut.

Operator control boxes can be a touch screen or button/switch operated with variations including:

- The powered bottom axis movement with a manually positioned top axis

- Powered top axis movement with some linear fixed bottom sleeves

- Powered top and bottom axis movement as a C-frame design edge trims

- The powered bottom axis movement with docking between the top and bottom knives

- Powered bottom axis movement with powered top axis movement

3. Fully Automatic Positioning System

3. Fully Automatic Positioning System

Fully automatic positioning systems are systems in which: Knife positioning is under the power via recipe selection through a Dienes slitter control system. Making it safer for users because the system works automatically without the need for physical intervention on the user’s part.

Automatic positioning systems may be with or without Quick Set. Quick set is an innovative technology developed by the Dienes Group, capable of simultaneously positioning all slitting stations. All of this while guaranteeing high levels of accuracy and repeatability.

Other types of automatic systems include:

- Pick and place systems

- Automatic-dedicated knife banks

- High-speed positioning systems. That use different combinations of our award-winning technology.

Depending on the requirements of each application, our team of experts determines which automatic system best fits your application.

4. Quick Set Positioning System

The last part of this blog, what is a positioning system? is Quick Set. As described above, Quick Set automatic positioning systems are systems in which positioning knives are via recipe selection.

Making use of the latest technologies available to the industry, Dienes Corporation designed an automatic positioning system. It utilizes specially designed adapters propelled by individual motors in conjunction with an absolute location device. As a result, this allows for precise and simultaneous movement of all cutting stations at once. The entire system is operated via an easy to use recipe-driven touch screen operator interface console.

Quick Set can be used on any application and can be retrofitted into most applications.

In conclusion, these systems are proven to be more reliable than conventional linear actuator systems. Moreover, it is faster with a simultaneous slitter positioning setup time of 30 seconds or less, depending upon the number of cuts. Quick Set can come in razor, crush and shear with three basic motor sizes.

The control system for the Dienes Corporation Quick Set slitter section makes use of a programmable controller. Secondly, there is an HMI touch screen for operator ease when entering new recipes and operating the slitter.

What is a Positioning System Conclusion

Do you still have questions about this blog, what is a positioning system? Dienes is happy to help! Our team will help customers find the positioning system that best suits their needs. Order your positioning system today or call us at 1-800-885-3452 if you have any questions.

Follow us on LinkedIn or Facebook for similar blog posts to this one!